Cool Fish RSW systems save installation work because the refrigeration plant is remotely located away from the catch hold. The alternative to Cool Fish is cold plates or evaporator coils in the catch hold. Cool Fish eliminates refrigerant pipes, cold plates and valves spread about the vessel where access is tight and the potential for damage and leaks is high. The corrosion risk is eliminated because there are no welded plates and tubes in salt water. Piping and hose are the only connection from the fish catch hold to the Cool Fish system. Swagelock® tube fittings are used for all connections that are not silver brazed, giving the best mechanical leak proof connection. Simple compact construction makes Cool Fish systems easy to install in tight spaces on smaller boats.

Big performance is delivered when your catch is chilled to the buyer’s specifications.

The Cool Fish barrel is made from PVC and is a full flow design that will pass any material that can be pumped. The one piece evaporator core is Navy alloy copper nickel tube. There are no dis-similar metals in salt water.

The refrigerant expansion valve is encapsulated in an epoxy casting for maximum protection for corrosion and vibration.

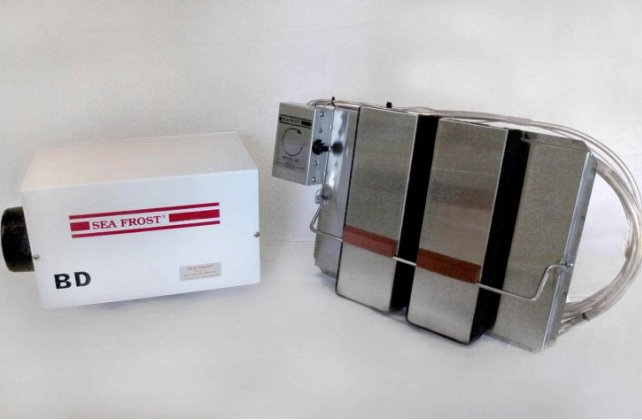

Engine Driven CoolFish

Single engine vessels can be fitted with the Engine Drive condensing section and compressor. A dedicated water pump either electric or belt driven can provide water for the refrigeration condenser.

The compact sea water condenser is Navy alloy copper nickel with a drawn copper rifled jacket for the refrigerant path. The receiver filter drier contains 6 oz. of molecular sieve desiccant for a reliable maintenance free operation. The receiver filter drier has a sight glass for charge inspection.